Stay up-to date on the

latest blogs. Join our

newsletter today!

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

How Do Freezers Work: All You Need To Know (2024)

Written by Team Ryze Chemie

13 mins read · May 21, 2024

Struggling to keep your lab samples at the perfect temperature? You're not alone. Many lab technicians face challenges in maintaining the right conditions for their chemical experiments. Understanding how freezers work can help you avoid these issues.

This article will explain the mechanics of freezers, ensuring your samples stay safe and your experiments run smoothly. By the end, you'll have the knowledge you need to keep your lab running efficiently.

Core Principles of Refrigeration (Tailored for Lab Settings)

Keeping your samples cold in the lab is crucial for successful research. But have you ever wondered how your freezer actually achieves those low temperatures? This section dives into the science behind refrigeration, focusing on the key principles that keep your precious samples safe and sound:

A. Vapor Compression Cycle:

Imagine a machine that pumps heat from one place to another. That's essentially what a refrigerator does! It uses a process called the vapor compression cycle, which works in a simple four-step loop:

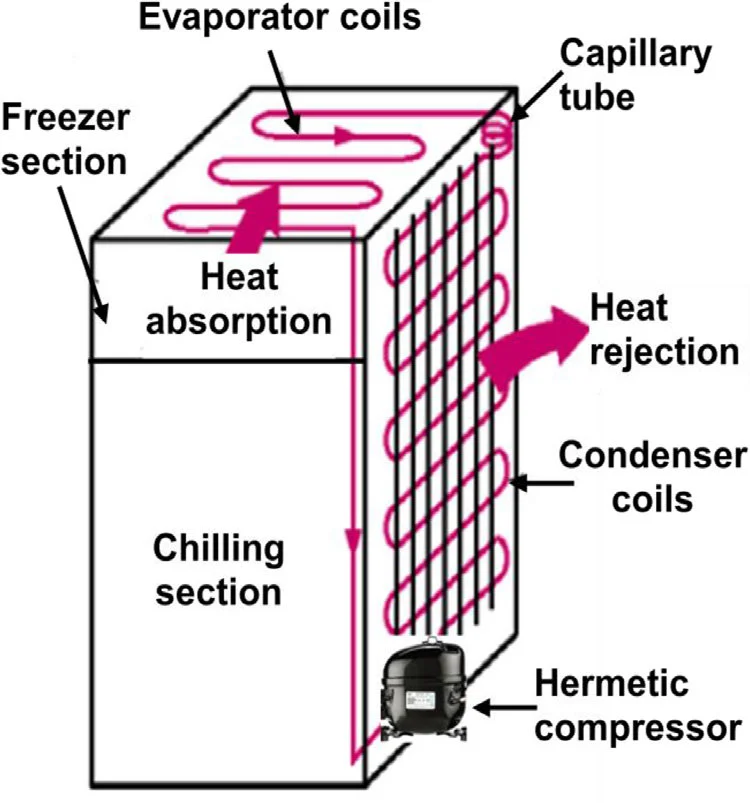

- Compression: A pump, called the compressor, squeezes a refrigerant (a special liquid that easily changes state) into a hot, high-pressure gas. This squeezing process concentrates the heat in the gas.

- Condensation: The hot, high-pressure gas travels through a coiled pipe called the condenser. This condenser is usually located on the back of your freezer, where you might feel hot air radiating. As the hot gas flows through the condenser coils, it loses heat to the surrounding environment, condensing back into a cool liquid.

- Expansion: The cool, high-pressure liquid then passes through a narrow valve called the metering device. This valve acts like a pinch in a hose, reducing the pressure on the liquid. As pressure drops, the liquid refrigerant rapidly expands and boils, absorbing heat from its surroundings in the process. This is why the evaporator feels cold.

- Evaporation: The cold, low-pressure liquid refrigerant reaches the evaporator, another set of coils located inside the freezer compartment. Here, the refrigerant absorbs heat from the warm air and stored samples, causing it to evaporate back into a gas. This cycle then repeats, continuously removing heat from the freezer and releasing it into the environment.

By constantly absorbing heat and releasing it outside, the refrigerator maintains a cold environment for your valuable samples.

B. Refrigerant Selection for Labs:

Choosing the right refrigerant for your lab freezer is like picking the right tool for the job. Here's why it matters:

- Temperature Needs: Different refrigerants excel at achieving specific temperature ranges. Some are ideal for standard cold storage, while others can reach ultra-low temperatures for specialized applications.

- Sample Compatibility: Certain refrigerants might react with your samples, leading to contamination or degradation. Choosing a compatible refrigerant is essential.

- Environmental Impact: Traditionally used refrigerants can sometimes contribute to greenhouse gas emissions or ozone depletion. Eco-friendly options are becoming increasingly popular.

For lab freezers, hydrocarbon refrigerants are gaining traction. These are natural refrigerants derived from propane, butane, or their blends. Here's why they might be a good fit for your lab:

- Environmentally Friendly: Hydrocarbon refrigerants have a very low Global Warming Potential (GWP) compared to traditional options, making them a sustainable choice.

- Energy Efficient: They can also offer improved energy efficiency, translating to lower operating costs for your lab.

Safety First!

While hydrocarbon refrigerants offer several benefits, it's important to consider safety aspects as well. These refrigerants are generally classified as mildly flammable. Always consult your freezer's manual and safety data sheets (SDS) for the specific refrigerant used and proper handling procedures.

Understanding the basic principles of refrigeration and the importance of refrigerant selection empowers you to make informed choices about your lab equipment. By keeping these factors in mind, you can ensure your samples are stored under the optimal conditions for successful research.

With a good grasp of these principles, it's time to dive deeper into the specific components of lab freezers.

Deep Dive into Freezer Components and their Functions (Lab-Specific Focus)

Understanding your lab freezer's internal workings is crucial for maintaining optimal performance and ensuring the safe storage of your valuable samples. This section dives deep into the key components and their functions, focusing on their importance in a laboratory setting:

1) Compressor:

The compressor is the powerhouse of your freezer. It acts like a pump, drawing in low-pressure refrigerant vapor and compressing it. This compression process significantly increases the pressure and temperature of the refrigerant. Now hot and highly pressurized, the refrigerant is ready to release its heat.

Lab-Friendly Compressor Options:

- Reciprocating Compressors: These work like a piston engine, compressing the refrigerant with a back-and-forth motion. They are reliable and widely used, but can be noisy.

- Scroll Compressors: These utilize interlocking scrolls to compress the refrigerant. They offer quieter operation and good efficiency, making them a popular choice for laboratories.

2) Condenser:

The hot, pressurized refrigerant from the compressor heads to the condenser. Here, the opposite happens. The condenser acts like a heat exchanger, allowing the high-temperature refrigerant to release its heat energy into the surrounding environment (usually by air or water). As the refrigerant cools down, it condenses back into a liquid state.

Maintaining Peak Performance:

In a lab setting, consistent performance is vital. A dirty condenser, clogged with dust or debris, restricts airflow and hinders the heat exchange process. This can lead to your freezer working harder, using more energy, and potentially causing overheating. Regular cleaning of the condenser fins ensures optimal heat removal and efficient operation of your freezer.

3) Evaporator:

The cooled and condensed liquid refrigerant now travels to the evaporator. This component plays a critical role – it absorbs heat from the freezer chamber. The low-pressure refrigerant inside the evaporator readily absorbs heat from its surroundings, causing it to boil and turn back into a vapor. This process of evaporation removes heat from the chamber, maintaining the desired cold temperature for your samples.

Evaporator Designs for Specific Needs:

- Finned-Tube Evaporators: These consist of coils with fins that increase surface area for better heat transfer. They offer a good balance of cooling speed and temperature uniformity.

- Plate Evaporators: These flat, plate-shaped designs provide a highly efficient and fast-acting cooling solution. However, they might not offer the same level of temperature uniformity as finned-tube models.

Choosing the right evaporator type depends on your specific needs. If rapid cooling is a priority, a plate evaporator might be ideal. For applications requiring very precise and uniform temperatures, a finned-tube evaporator could be a better choice.

4) Metering Device:

Before reaching the evaporator, the liquid refrigerant needs one final adjustment. The metering device, either a capillary tube or an expansion valve, regulates the pressure and flow of the refrigerant. This controlled flow ensures the evaporator receives the optimal amount of refrigerant for efficient heat absorption.

Capillary Tube vs. Expansion Valve: Understanding the Choices

- Capillary Tube: This is a simple, cost-effective option. It's a narrow tube that restricts the flow of refrigerant based on pressure differences. However, it offers limited control over the flow rate.

- Expansion Valve: This electronically controlled valve provides more precise control over the refrigerant flow. This allows for better temperature control and efficiency, making it a good choice for critical sample storage.

The choice between a capillary tube and an expansion valve depends on your budget and the specific temperature control requirements for your lab.

By understanding the roles of these key components, you can ensure your lab freezer operates efficiently and maintains the optimal temperature for your valuable samples. Remember, proper maintenance, including regular cleaning of the condenser, is crucial for long-lasting performance and reliable sample storage.

Understanding these components is key to managing your lab freezer. Next, let's look at the control and monitoring systems that keep everything running smoothly.

Freezer Controls and Monitoring Systems (Critical for Labs)

For laboratory personnel, freezers are vital equipment for storing a wide range of chemicals and biological samples. These materials often require precise and consistent temperatures to maintain their integrity and function. This is where freezer controls and monitoring systems come into play:

A. Temperature Control Systems:

Two main types of temperature control systems are found in lab freezers:

Mechanical Thermostats: These are traditional systems that use a dial or lever to set a desired temperature. A sensor inside the freezer detects temperature changes and triggers a physical response, like turning on a compressor to cool the chamber or a heater to maintain warmth. While simple and reliable, mechanical thermostats may not offer the same level of precision as digital controllers.

Digital Controllers: Modern freezers often use digital controllers. These systems feature a digital display showing the current temperature and allow for more precise temperature settings. They use electronic sensors and microprocessors to regulate the cooling or heating system, resulting in tighter temperature control.

Importance of Precise Temperature Control:

The specific temperature needs of chemicals and samples vary greatly. Enzymes, for instance, require very cold temperatures (-80°C or lower) to remain active, while some medications might degrade if stored below freezing. Here's why precise temperature control is crucial:

- Maintaining Chemical Stability: Many chemicals react differently at various temperatures. Precise control ensures they remain stable and usable in your experiments.

- Preserving Sample Integrity: Biological samples, like tissues or cell cultures, can be damaged by even slight temperature fluctuations. Consistent cold storage helps maintain their structure and function.

- Ensuring Accurate Results: Fluctuations in temperature can affect chemical reactions and biological processes. Consistent temperatures minimize these variations and ensure reliable results in your research.

B. Temperature Monitoring Systems:

Even with the best control systems, unexpected events can happen. This is why continuous temperature monitoring is essential in lab freezers. Here's how it safeguards your valuable samples:

- Early Detection of Problems: Monitoring systems alert you to temperature deviations from the set point. This allows you to take corrective action before your samples are compromised.

- Data Recording and Documentation: Many monitoring systems record temperature data over time. This data is crucial for maintaining records and ensuring compliance with regulatory requirements.

- Peace of Mind: Knowing your freezer temperature is constantly monitored provides peace of mind, allowing you to focus on your research without constant worry.

Different Monitoring Systems:

Several options are available for monitoring freezer temperatures:

- Internal Thermometers: These are basic but reliable tools placed inside the freezer. They offer a quick visual check of the current temperature.

- Data Loggers: These electronic devices continuously record temperature data over time. Data loggers can be downloaded to a computer for analysis, providing a detailed history of temperature fluctuations.

- Alarm Systems: Advanced monitoring systems incorporate alarms that trigger alerts (e.g., email, text message) if the temperature deviates from the set point. This allows for immediate intervention to protect your samples.

C. Temperature Alarms and Alerts:

Setting and maintaining proper alarm protocols is vital for safeguarding your samples. Here's why:

- Early Warning of Malfunctions: Alarms notify you of potential problems, like a power outage or freezer malfunction, before your samples are at risk.

- Quick Response Time: Early notification allows you to take corrective action promptly, minimizing damage to your research materials.

- Preventative Measures: Regular alarm testing ensures the system functions properly, giving you confidence that your samples are protected.

Here are some key points for setting alarms:

- Set High and Low Temperature Excursions: Set alarms for both high and low temperatures that deviate from the desired range.

- Customize Alarm Thresholds: Adjust the sensitivity of the alarms based on the specific needs of your samples.

- Test Alarms Regularly: Regularly test your alarm system to ensure it functions correctly.

By implementing effective freezer controls and monitoring systems, you can ensure the safe and proper storage of your valuable lab chemicals and samples. This, in turn, contributes to the success of your research endeavors.

With these systems in place, maintaining your freezer becomes much easier. Let's move on to some best practices for keeping your lab freezer in top condition.

Maintaining Optimal Freezer Performance in a Lab Setting

Maintaining your lab freezer is essential for reliable performance. In this section, we will provide practical tips and routines to ensure your freezer operates at its best:

1) Proper Loading and Storage Practices

Organization is Key: Arrange items in your freezer to allow for proper air circulation. Cold air needs to flow freely around containers to maintain consistent temperatures. Avoid stacking items directly in front of air vents. Leave space between containers and the back wall of the freezer. Utilize freezer racks for organized storage and improved airflow.

Label Everything: Clearly label all containers with contents, date of storage, and owner information. This simplifies finding items quickly, minimizing door opening times. Less time spent with the door open translates to less temperature fluctuation inside the freezer.

Don't Overload: Avoid cramming your freezer. A crowded freezer restricts airflow, reducing efficiency and increasing energy consumption. Leave enough space for the door to close properly, creating a tight seal.

2) Defrosting Schedules and Techniques

Why Defrost? Ice buildup on the freezer walls reduces usable space and insulates the contents, hindering the freezer's ability to maintain desired temperatures. Regular defrosting prevents ice accumulation, ensuring optimal performance.

Defrosting Methods:

- Manual Defrosting: This method involves turning off the freezer, removing all contents, and allowing the ice to melt naturally or with the help of a pan of hot water (not boiling). This method requires planning and can be time-consuming. It's best suited for smaller freezers or those used infrequently.

- Automatic Defrosting: Many modern lab freezers have built-in defrost cycles. These cycles automatically raise the temperature within the freezer for a short period, melting any accumulated ice. This is a convenient and time-saving option for busy labs.

- Choosing a Defrosting Method: The best method depends on your specific freezer model and usage patterns. Consult your freezer's manual for recommended defrosting procedures and frequency.

3) Regular Maintenance and Service

Preventative Maintenance is Essential: Regularly scheduled maintenance by qualified technicians is crucial for keeping your lab freezer running smoothly. Think of it as preventive care for your valuable equipment. Just like a car needs regular oil changes and tune-ups, your freezer needs professional attention to maintain optimal performance and avoid costly breakdowns.

What Does Maintenance Involve?

Maintenance typically includes tasks like cleaning condenser coils, checking door seals for wear and tear, inspecting temperature sensors for accuracy, and lubricating moving parts. These actions ensure efficient operation and extend the lifespan of your freezer.

By following these simple guidelines, you can ensure your lab freezer operates at peak performance, safeguarding the integrity of your research materials. Remember, a well-maintained freezer is a reliable partner in your scientific endeavors.

Conclusion

In conclusion, freezers play a crucial role in many laboratory settings. They maintain low temperatures to preserve samples and reagents.

By removing heat through a refrigeration cycle, freezers keep materials stable and safe. Understanding how they work helps you use them more effectively. Regular maintenance ensures optimal performance and longevity.

Embrace the benefits of your freezer to enhance your lab’s productivity. Stay informed, stay efficient, and keep your materials in perfect condition.

Latest Blogs